NYC's Most Trusted Garment Manufacturer

We Proudly Support and Work With

-

Designers

-

Start-Ups

-

Small Businesses

-

Upcoming Fashion Brands

We’re here to help.

All you need is a dollar and dream!

Well, there’s a little more required. We are happy to help up and coming designers, but before you get your feet wet, here’s what to expect…

Be prepared for some garment development upfront costs including:

- 1st Pattern

- Cut & Sew Sample

- Fitting / Resizing

- Grading / Marker

- Pattern Corrections

- Fabric Estimates

- Freight & Tariff

- And other additional fees…

The cost of production is determined by the garment, fabric weight, consumption, quantity, and construction. This is determined individually per project, we cannot provide estimates without having project-specific information. Please complete our quote request form to inquire about estimates.

We can begin garment construction from a single design sketch, tech-packs, fabric swatches, and similar garment samples for concepts. We only create 1st patterns and cut & sew samples for the purpose of mass production meeting our MOQs.

In order to get started, you must be able to meet our MOQs of 200 per style for New York production and 400 per style for overseas production, this is also dependent on the garment. To give you an idea, the average garment made in NYC is around $30-$50, not including fabric, trim, and garment development. A good rule is to be prepared for a $10,000+ budget for the production of a single garment.

* Production costs vary per project. This is just a ballpark budget to have prepared to get started. *

Please note:

- All new startups must have a sales and budget to meet our MOQs. To give you an idea, the average cost of generic sportswear costs around $35 each, and t-shirts are about $15 each to be made in NYC. This does not include fabric or trim and must meet the minimum 200 MOQ per style.

- We DO NOT create samples for selling purposes, all patterns, and cut & sew samples must be for mass production. We only will do patterns and samples for confirmed production orders that meet our minimums.

If you just need a pattern and sample for internet advertising or for selling purposes it would be best for you to find a reputable pattern and sample room online since we only make patterns and samples for orders that will meet our minimum quantities as listed. - * All new designers must be able to meet our 200 domestic and 400 overseas MOQs per style. *

Looking for a More In-Depth Conversation?

Have a 1-on-1 consulting meeting with Teddy Sadaka, the CEO of Apparel Production Inc.

The Garment Manufacturing Process

Sketch and Design

The first step of any piece of clothing is the initial sketch and design. The purpose of a sketch is to give a visual representation of what direction the garment should follow. This gives a starting platform for both fashion designers as well as manufacturers. It should focus on characteristics such as color combinations, embellishments, proportions, pocket positions, accessories, etc.

Things to consider when creating the initial sketch:

- Garment Complexity

- Fabric Type & Usage

- Sizing proportions

- Easily Distinguishable

- Single Style vs. Mass Production

We help designers turn their initial designs into a first sample garment to help them get a better visualization to help make design adjustments and revisions.

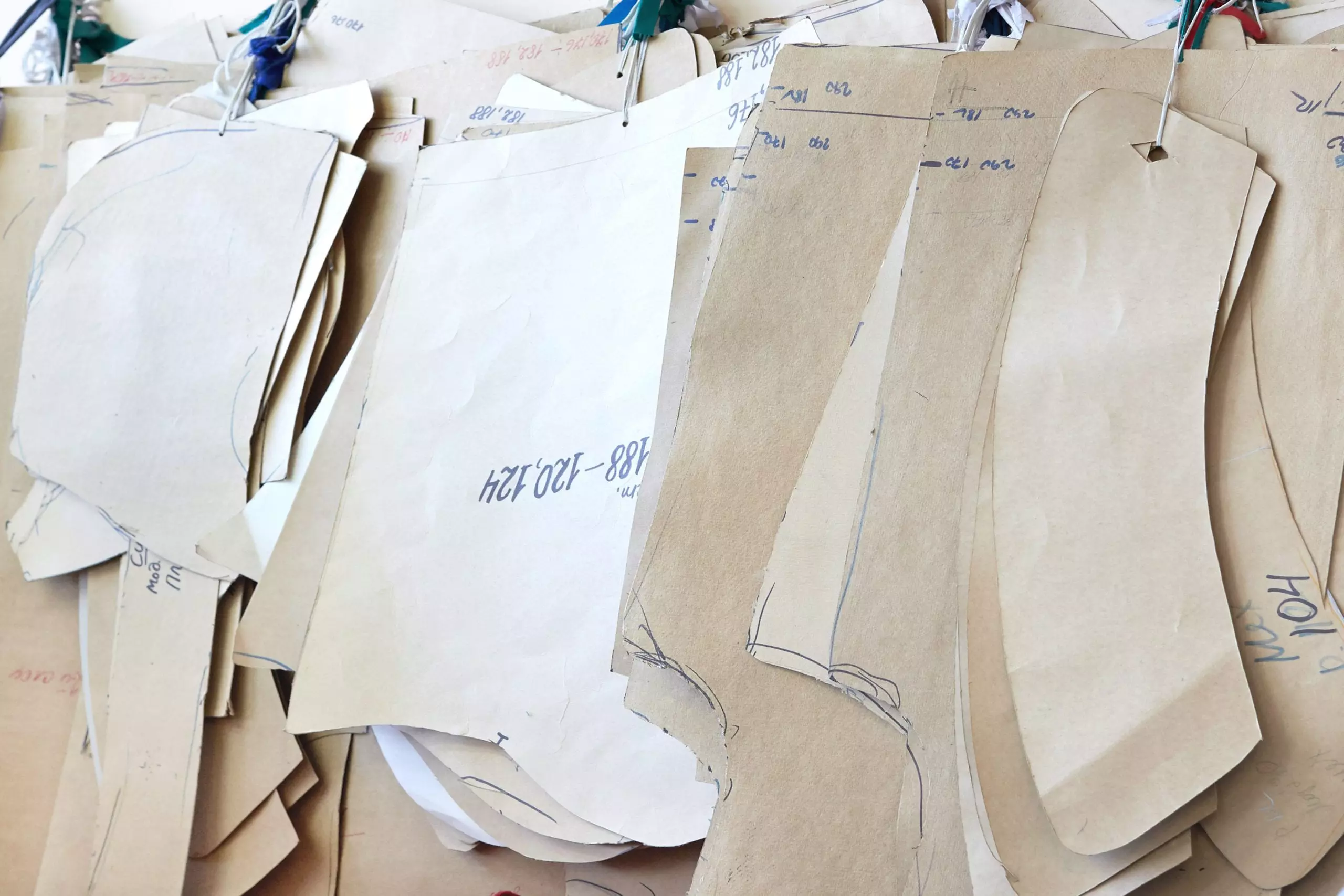

Pattern Making

An original pattern must be developed for each design. This serves as the template from which the parts of the garment are traced onto fabric before being cut and assembled. This template shows the required measurements for each piece to construct the garment. Patterns of different sizes are produced from the original master pattern.

This can be done manually or computerized. Patterns are graded according to size charts by industry standards. The grader uses these patterns for sizing and the marker uses them for the fabric layout.

CADs & Tech Packs

Computer-Aided Design (CAD) uses computer software to assist the process of creation, modification, development, optimization, and analysis. Computer-aided designers in the fashion industry use computer software to create sketches and other designs used to create clothes, accessories, shoes, intimate apparel, and more.

Tech packs are a complete collection of data covering all of the specifications of a garment. The tech pack essentially serves as a technical blueprint for the garment. The best tech packs include images, fabric details, accessory details, label information, positioning, and meticulous measurements. This helps reduce mistakes and improve communication, making the production process between the designer and manufacturer easier to understand and follow, resulting in less mistakes. They also tend to reduce lead times and turn arounds. They are not required, but help with product development.

Sample & Fitting

A garment sample, or pre-production garment, is essentially the proto-type of a style that covers: garment fit, size measurement, color, fabric and trims quality checking, and overall build before bulk manufacturing.

Upon creating the 1st sample, we offer fittings on-site with our pattern makers. This allows for all pattern corrections to be completed quickly and efficiently.

A fit model is a trained professional model who can critique and advise on the fit of your garment. It is not required, but it helps to make sure your apparel has the right fit. Some designers choose to create the sample in their size for fittings, or use friends to model.

Fabric Sourcing

There are so many variations to fabrics that it’s difficult to provide all options to the designer – it’s like searching for a needle in a haystack. Instead, we ask that you bring a sample of the fabric you want to use.

Things to keep in mind are the amount of garments that will need to be produced, depending on the type of fabric can increase cost and lead time. Fabric prices are always based on the length, not the width. Laying out pattern pieces before ordering can help give an estimate on how much fabric may be needed for a single garment. It is important to have properly marked, graded, and digitized patterns to help reduce fabric yield, ultimately reducing total fabric waste.

With our extensive network, we can send fabric swatches directly to our suppliers to source and provide color options. This gives our clients more options when selecting the fabric for their lines.

Sewing and Cutting

The physical manufacturing process and assembly of the garments. This entails the cutting of the fabric from the finalized pattern, laying out each piece, hand-sewing each piece together, and adding any additional details/accessories.

Our factories are SGS approved, meaning that our services are compliant with national and international regulations and standards. Our New York City factory offers TWO full production floors and a pattern room with machines ranging from straight sewers & merrow machines, to jacket sleeve setters & shoulder press machines.

After the garment is completed, it undergoes extensive quality control to ensure there are no manufacturing defects before shipping. This allows brands to fully produce their garments domestically in our vertically integrated factories.

We also offer overseas production for higher quantity orders. All of our overseas facilities are SGS approved and ethnically regulated to match the highest standard of quality. We have Research and Development teams overseas to monitor the manufacturing process from start to finish.

Packing & Shipping

Our duty, tariff, and freight services ship directly to our client’s storefronts, warehouses, or offices.

All garments are properly wrapped to ensure the clothing are safe and undamaged during shipping. Shipping times depend on the scope of the project and the number of garments being sent out. Be sure to take into consideration that overseas shipping may cause longer turnaround times.